Computer Vision Quality Control: Transforming Manufacturing Inspection

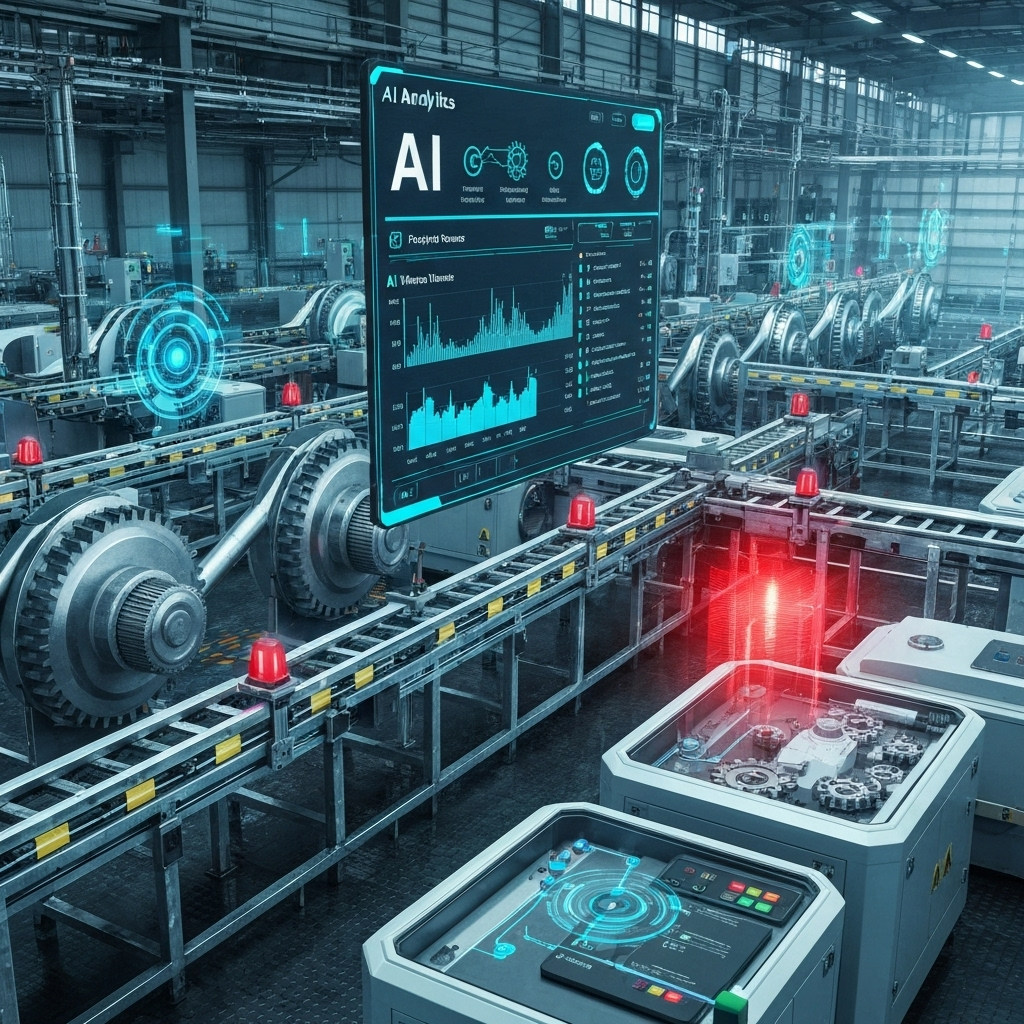

How AI-powered visual inspection systems revolutionize quality control. Real-time defect detection, automated sorting, and integration with production lines.

Traditional quality control relies on human inspectors who can miss defects due to fatigue, inconsistency, or the sheer volume of products. Computer vision quality control systems provide 24/7 inspection capabilities with consistent accuracy, detecting defects that human eyes might miss while processing thousands of items per hour.

Automated Defect Detection Systems

Modern computer vision systems can identify surface defects, dimensional variations, color inconsistencies, and assembly errors with sub-millimeter precision. Deep learning models trained on thousands of defect examples learn to recognize patterns that indicate quality issues, often surpassing human inspection accuracy.

Real-Time Integration with Production Lines

Computer vision systems integrate directly with manufacturing equipment, providing instant feedback to production processes. When defects are detected, the system can automatically reject products, adjust machine parameters, or alert operators, preventing defective products from reaching customers.

Implementation Challenges and Solutions

Successful deployment requires addressing lighting variations, product positioning inconsistencies, and environmental factors. We use specialized industrial cameras, controlled lighting systems, and robust image processing algorithms that maintain accuracy across different production conditions.

ROI and Performance Metrics

Computer vision quality control typically reduces inspection costs by 40-60% while improving defect detection rates by 25-50%. The system pays for itself through reduced waste, fewer customer returns, and improved brand reputation. Implementation ROI is usually achieved within 12-18 months.

Computer vision quality control represents the future of manufacturing inspection, providing consistent, accurate, and cost-effective quality assurance. The technology is mature and ready for widespread industrial deployment.