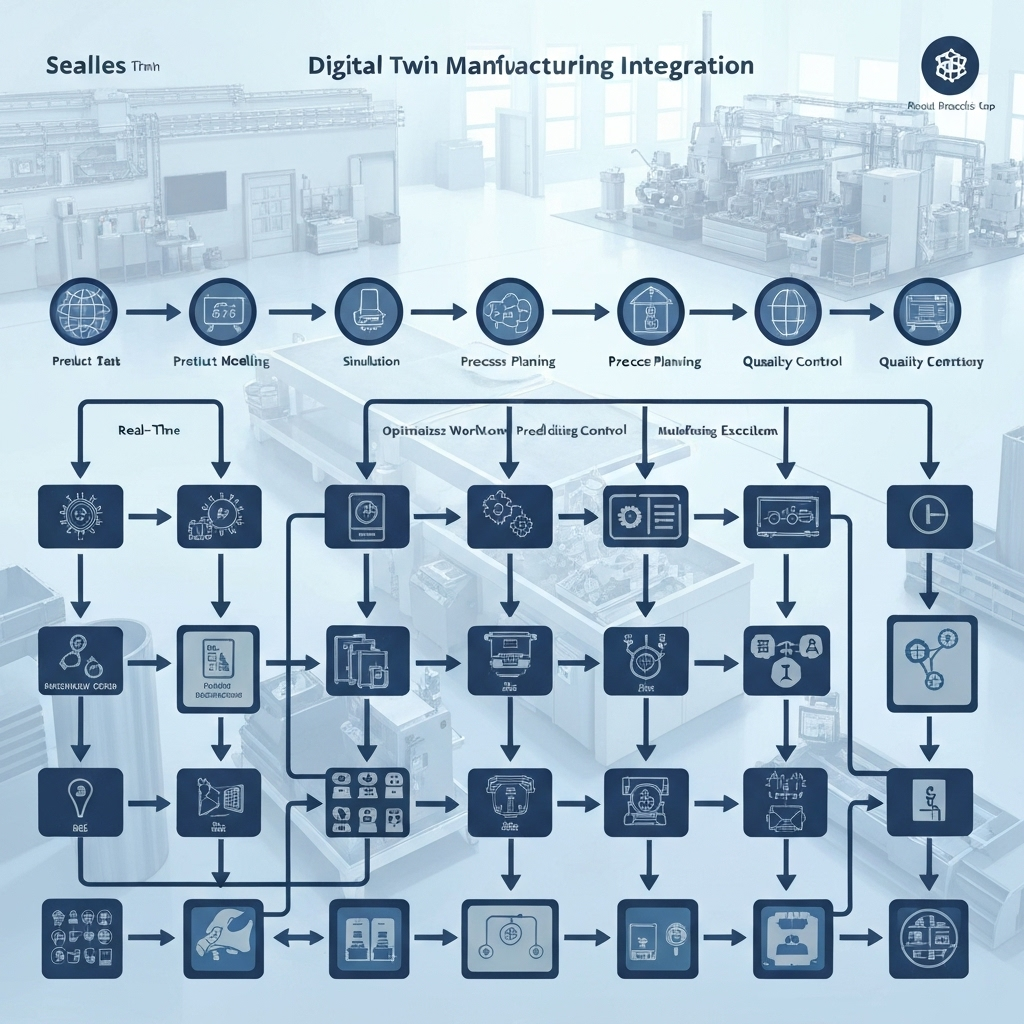

Industry 4.0 PLM Integration: Digital Transformation in Manufacturing

How Product Lifecycle Management systems integrate with Industry 4.0 technologies. Digital twins, IoT connectivity, and smart manufacturing workflows.

Industry 4.0 represents the convergence of physical and digital manufacturing systems. Product Lifecycle Management (PLM) platforms serve as the central nervous system, connecting design, production, and maintenance data across the entire product lifecycle. This integration enables smart factories that can adapt, optimize, and self-manage production processes.

PLM as the Digital Backbone

Modern PLM systems go beyond traditional document management to become comprehensive digital platforms. They integrate CAD data, manufacturing instructions, quality specifications, and maintenance procedures into a single source of truth that feeds smart manufacturing systems.

IoT Integration and Digital Twins

PLM systems now connect directly to IoT sensors on the factory floor, creating digital twins that mirror physical products and processes. This real-time connection enables predictive maintenance, quality optimization, and continuous improvement based on actual production data.

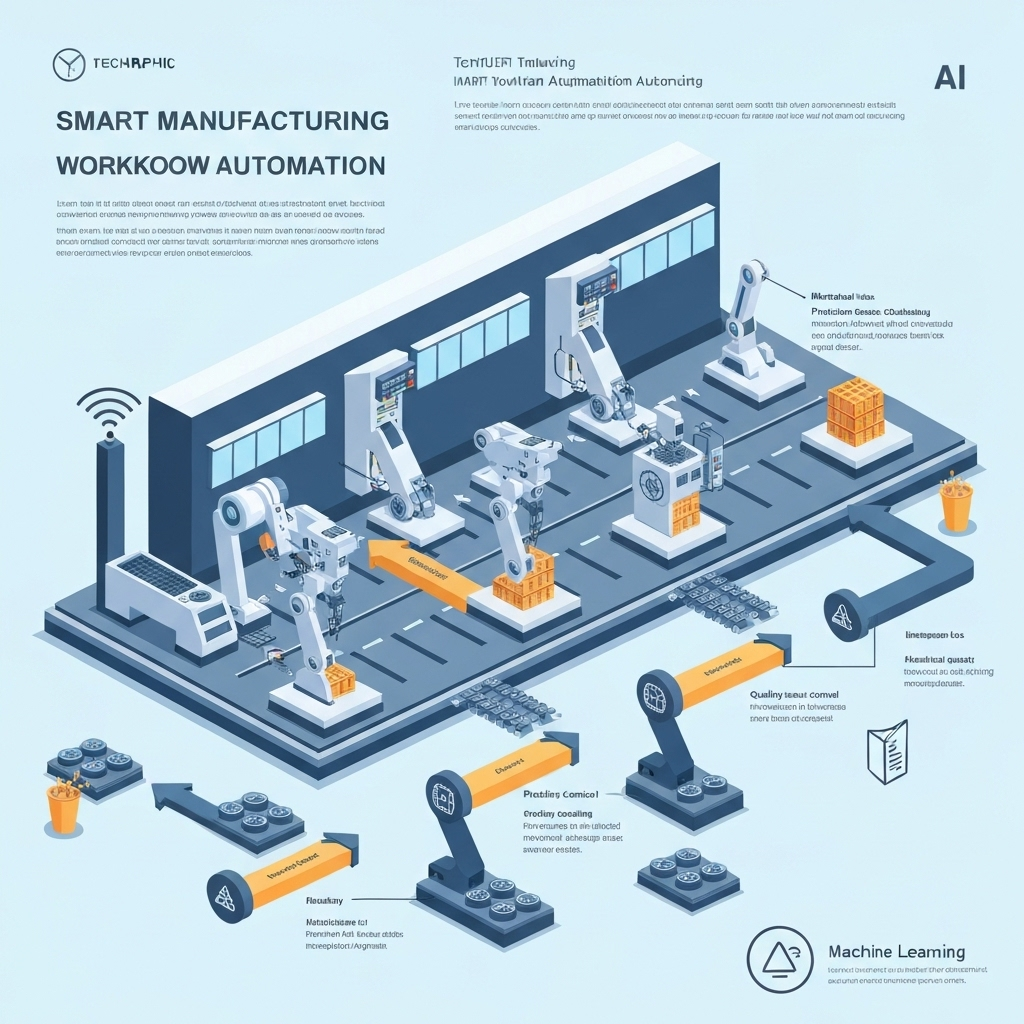

Smart Manufacturing Workflows

Industry 4.0 PLM integration enables autonomous production workflows. When design changes occur, the system automatically updates manufacturing instructions, adjusts quality parameters, and notifies relevant stakeholders. This reduces lead times and eliminates manual coordination errors.

Implementation Strategy

Successful PLM-Industry 4.0 integration requires careful planning and phased implementation. Start with pilot programs on specific product lines, establish data standards and integration protocols, then gradually expand to full enterprise deployment. Change management is as important as technology implementation.

Industry 4.0 PLM integration transforms manufacturing from reactive to predictive operations. The key is viewing PLM not as a document repository but as the central intelligence system that orchestrates smart manufacturing processes.