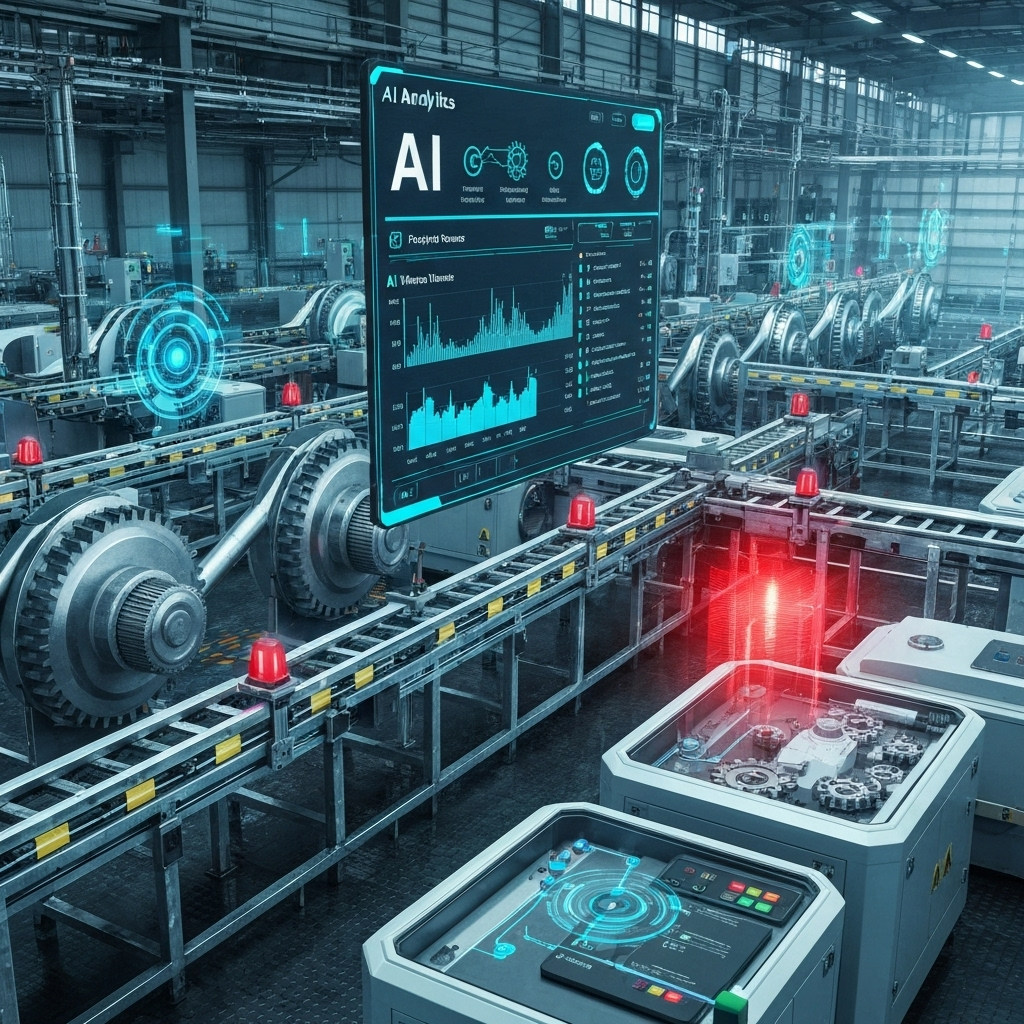

AI + IoT Predictive Maintenance: A Complete Implementation Guide

How IoT sensors and machine learning models work together to predict equipment failures. Real-world deployment strategies and ROI analysis.

Predictive maintenance represents the convergence of IoT sensing and AI analytics. By monitoring equipment health in real-time and applying machine learning to historical failure patterns, organizations can shift from reactive repairs to proactive maintenance, reducing downtime by up to 50% and maintenance costs by 25%.

IoT Sensor Integration Strategy

Successful predictive maintenance starts with the right sensors in the right places. Vibration sensors detect bearing wear, temperature sensors identify overheating, and current sensors reveal motor inefficiencies. The key is balancing sensor coverage with cost—focus on critical equipment first.

Machine Learning Models for Failure Prediction

We deploy ensemble models combining time series analysis, anomaly detection, and classification algorithms. LSTM networks excel at capturing temporal patterns in sensor data, while isolation forests identify unusual behavior. The challenge is handling imbalanced datasets—failures are rare events.

Edge Computing for Real-Time Analysis

Critical equipment can't wait for cloud processing. Edge computing devices perform real-time analysis at the equipment level, triggering immediate alerts for dangerous conditions while sending aggregated data to the cloud for long-term trend analysis.

Implementation Roadmap

Start with pilot programs on 3-5 critical assets. Establish baseline performance metrics, deploy sensors, and collect 6-12 months of data before training predictive models. Gradually expand to additional equipment as you prove ROI and refine your approach.

AI+IoT predictive maintenance transforms maintenance from a cost center to a competitive advantage. The technology is mature, but success depends on careful sensor selection, robust data pipelines, and change management to shift from reactive to predictive mindsets.